3D Technology and the Future of Design

Across the globe, infrastructure is changing to meet the needs of modern communities, and the technology used to plan, design and construct it is changing too. From 3D modeling to augmented reality, the AEC industry is increasingly implementing innovative tools and techniques to keep up with an evolving world.

As Major Projects Lead at Benesch and a Bentley Accredited Scholar, Ryan Thady, PE, PMP, VMA sheds some light on the benefits and challenges these technological advances bring.

Meet Our Expert

How is 3D technology impacting how designers approach projects?

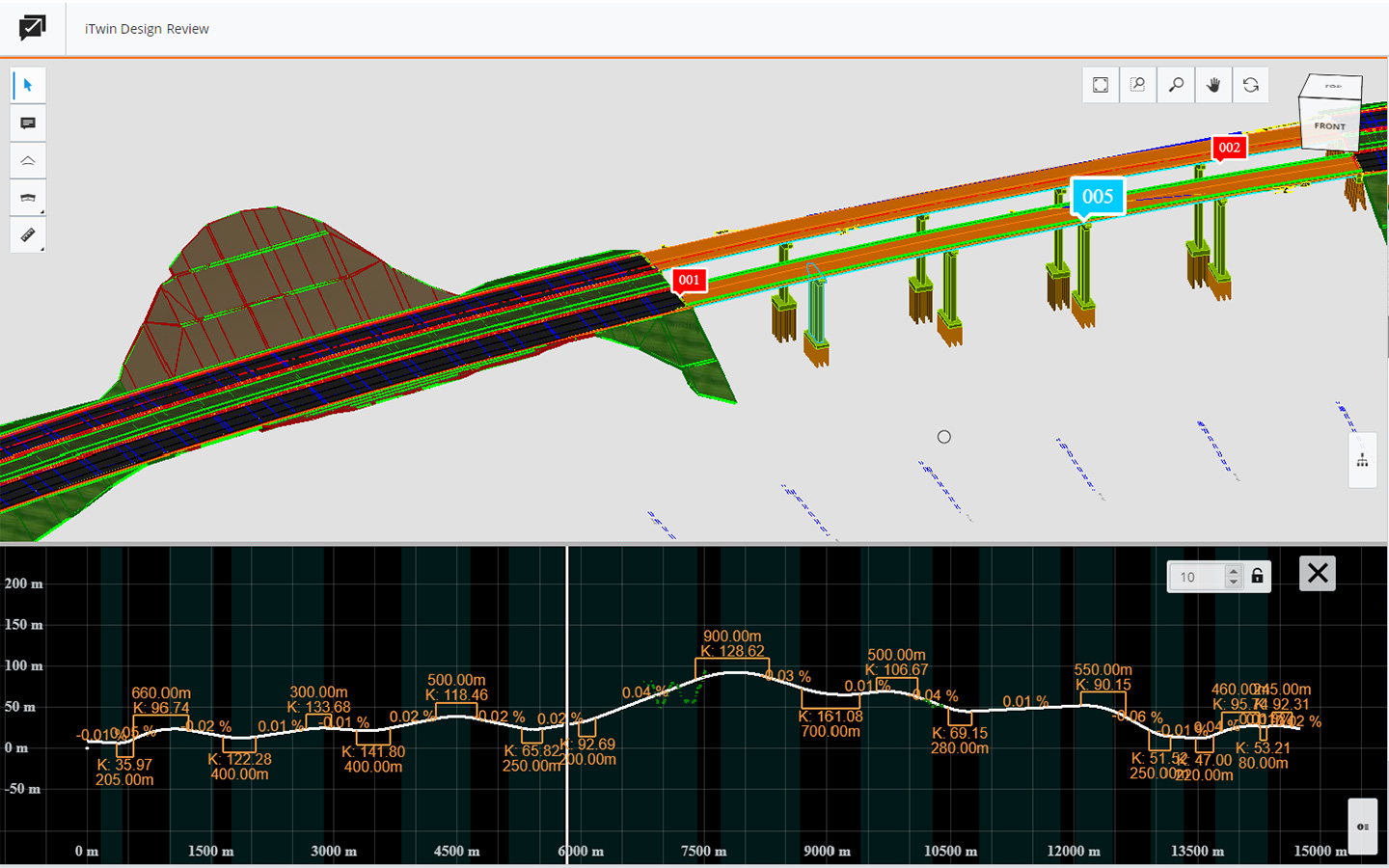

Design is really being impacted by our ability to move out of the 2D space. New technology is allowing us to deliver work in 3D and 4D, essentially transforming how designers, contractors, construction management staff and clients visualize and review projects all while removing cumbersome steps from the process.

When a design is delivered traditionally, the builder is left to create the model, leaving certain elements up to their interpretation. With modeled delivery, the designer can ensure that the client sees the design as intended, allowing for an unprecedented level of detail and control. Implementing 3D model reviews further amplifies the benefits. We eliminate the need for 2D cut sheets, streamline the review process and save time by working in an environment purpose-built for discipline-specific reviews.

Automated machine controls are worth mentioning as well. Increasingly, we’re able to create models that can be read by construction equipment. After reading the model, the machine uses data from satellites or total stations to ensure that the machine operators can accurately position the machinery. Machine control solutions on excavators, dozers and graders save operators time, money and fuel improving accuracy and increasing performance.

Why should clients be interested in 3D technology being used on their projects?

Aside from the benefits of modeled delivery and automated machine controls, there is certainly something to be said about the strides we’re taking in terms of visualization – honestly, it’s game changing.

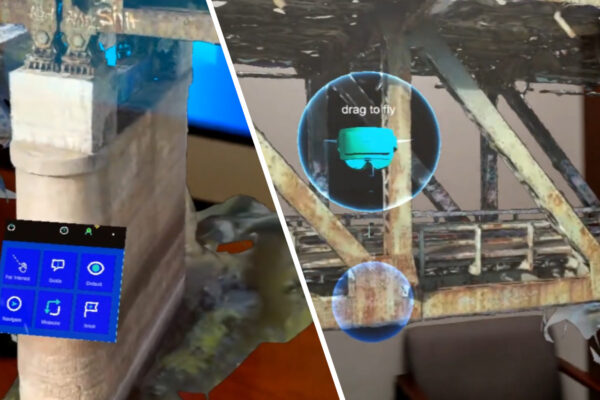

Currently, we have these models that live in computers, but translating and visualizing that in the actual environment can be a challenge. Using virtual reality and augmented reality, we’re working to either bring more of the environment into the model or to bring the model into the actual environment.

Imagine being out in the field, holding up your phone’s camera and seeing your project come to life in front of you. Suddenly you can identify environmental challenges, explore underground elements and see exactly how your plans shape up on site. This level of visualization helps both designer and client think through the built environment in more detail than ever. Beyond that, you’re able to actually interact with the model – take measurements, access sub elements, see how things will be built… the list goes on. In a manner of speaking, clients are essentially able to take the design out for a test drive. This technology also provides the added benefit of aiding the project stakeholders and general public in understanding how the proposed improvements will affect them.

What new challenges will need to be addressed as this technology advances?

Before I talk too much about the challenges, I think it is important to highlight the timeline of this type of technology both in our industry and in others. For centuries, engineers drafted with pen and paper. It wasn’t until the eighties that computers really started to take over and 3D design really started to take off. Then what seem to be more random events, such as the Pokémon Go craze of 2016, introduced the concept of 3D design and augmented reality to the masses. For us to be talking about this technology as the next wave of standard engineering approach only a few decades later is incredible and will take some time for people to adjust.

Because of that, there are some challenges we are going to have to work through. The level of detail we can get with these models is amazing, but it begs the question of how much is enough. It’s natural for people to want more and more and more, but it’s not always practical or necessary. Like with most things in the A/E/C industry, creating standards will be important as we move forward. And that’s also true as we start to consider the legal side of things. Work is being done throughout the industry to explore both the development of standards and any legal issues related to the use of these technologies.

While this isn’t exactly a challenge, another interesting thing to note is the differing perspectives in the industry. While some can’t wait to dive into the 3D space, there can always be a bit of resistance to change. This wave of technological advances will take some time for people to adapt to, but with how quickly the world is changing, I’m confident even our most traditional colleagues will see the benefits. On the flip side, we don’t want to move so fast that it becomes the wild west – that’s where those industry standards come in again.

What is helping to advance these technologies in the industry?

Something that immediately comes to mind is the Bentley Premier Scholar Accreditation program. Bentley, the software developer behind products like OpenRoads, created this program to offer select users a technical bootcamp that will help them advance their skills. As a Bentley Scholar myself, I can say that both this program and the people who are selected to participate will be instrumental in advancing 3D technology in the industry. Benesch is really working to help facilitate the implementation of this tech with a value engineering mindset. When working on projects, yes, I want to help the tech advance in the industry, but what I am really focused on is finding what is most efficient for the client. That means our methods need to evolve as new technology is available.

Another thing that I think is really helpful is when companies put in effort to train and educate staff. At Benesch, we put a lot of emphasis on learning and development, and that includes encouraging staff to keep up with the latest technology in the industry. We’ve actually created mini think tanks through Benesch Tech Groups and User Groups. They bring together employees from across the company that are interested in this type of technology, and we work together to help it advance at Benesch. We’re also working to provide Bentley’s Open Platform and AutoDesk Civil 3D training to as many engineers as we can so that as 3D modeling becomes more prominent in the industry, Benesch is prepared to tackle any project for our clients.

What would be your advice for someone looking to incorporate 3D technology into their projects?

I’d recommend they seek out training in various programs and find a partner that really understands the capabilities of this technology and form a solid relationship with them. Since a lot of the standards around this work are still being developed, it is going to be important to be able to trust that the team you’ve partnered with will always work with your best interests in mind.

Benesch is proud to partner with Bentley as part of their early adopter program. We recognize the potential of 3D visualization and augmented reality tools and will continue to work to facilitate the use of these tool in the industry. Later this year, Benesch’s Bret Tremblay will be joining Roads and Bridges magazine for a discussion on this topic.

Follow us on LinkedIn for the latest news and insights.