Alternative Delivery

A Partnership That Pays Off

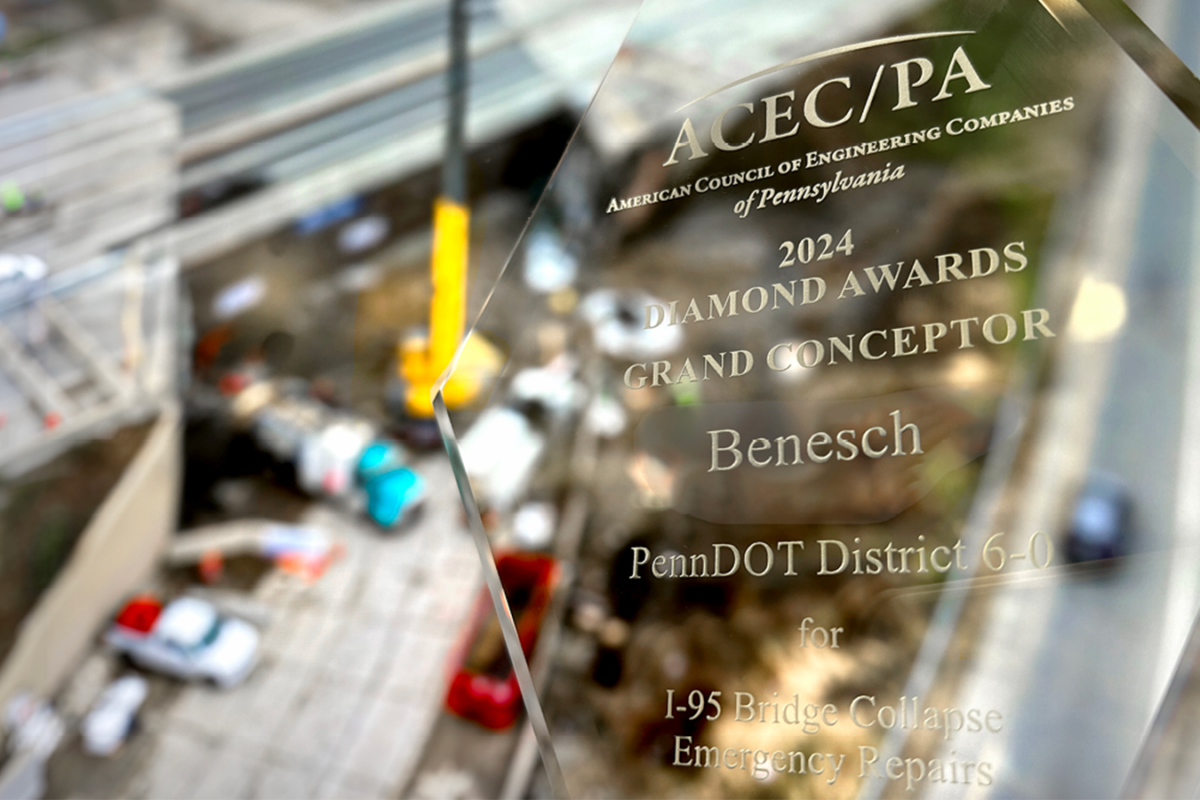

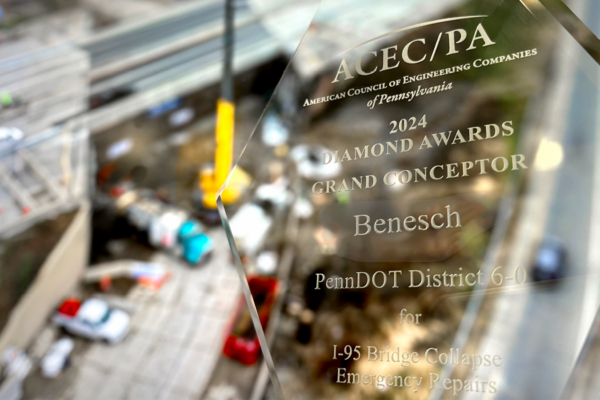

Constructability and innovation are integral to our designs, making Benesch the perfect project partner for agencies and contractors alike. In addition to our proven performance in supporting alternative delivery projects, our engineering approach is value-focused—no matter the project’s complexity, we can deliver cost-effective solutions that are realistic, reasonable and responsive to the given context of the assignment at hand. We turn our nationwide capacity and expertise into high-value solutions for local infrastructure challenges.

From design-build and progressive design build to P3 and CMGC, we can support even the most complex alternative delivery assignments.

Experience Across Delivery Methods

Benesch has a proven track record of supporting alternative delivery projects and providing cost-effective solutions. Our teams are laser-focused on creating constructable designs and being a realistic, reasonable and responsive project partner from start to finish.

Benesch brings a wealth of technical and constructability expertise to every project, ensuring a seamless and efficient design-build process from start to finish. Our collaborative approach enables us to work closely with your team to meet project goals and timelines.

Our team is adept at identifying winning alternative technical concepts (ATC), and we thrive on finding innovative solutions to complex challenges, optimizing design for constructability and maximizing cost-effectiveness. Whether it’s a traditional design-build or progressive design-build, our team will provide unparalleled expertise and support.

With a track record of successfully managing and delivering complex projects, Benesch has a wealth of experience with the CMGC approach. Our team excels at collaborating closely with owners and contractors to optimize project efficiency, control costs, and ensure timely delivery. We pride ourselves on our innovative problem-solving abilities, adaptability, and our deep understanding of construction processes and best practices.

With a history of delivering successful projects in collaboration with both public and private sectors, Benesch is well-versed in the complexities of P3 arrangements. Our innovative thinking and commitment to cutting-edge technologies and sustainable practices make us poised to create solutions that maximize project value and limit risk.

Value engineering is not just a process; it’s a mindset deeply ingrained in our engineers. We excel in identifying innovative ways to enhance project value while minimizing costs, without compromising quality or functionality—even when the project is already under construction. By meticulously analyzing every aspect of a project, we can pinpoint opportunities to deliver VECPs that result in substantial savings, accelerate project timelines, and increase overall performance of the end product.

We Are Constructability Experts

Alternative delivery empowers designers and contractors to take an integrated approach from initial design through to construction. To get the most out of this advantage, you need the right project partner.

When you partner with Benesch, you can be confident that we will design to your strengths. Because we’ve led both design and construction management efforts on projects large and small, we understand the importance of collaborating with contractors and prioritizing constructability. Our extensive experience in all major civil engineering markets—from water and wastewater systems to complex transportation infrastructure designs—gives us the ability to tackle a wide range of challenges.

Weighing the Alternatives

Pivotal to the success of alternative delivery projects—both in being selected and in delivering the final project—is the ability to quickly identify time and cost saving alternatives. Our value-focused mindset coupled with our knowledge of innovative techniques and emerging technologies allows us to develop alternative technical concepts (ATC) that are cost-effective, innovative and implementable.

By working hand in hand with our project partners to evaluate potential design modifications from the very start, we give the team a competitive advantage.

Putting Value Engineering to Work

Sometimes even the best, most thorough project plans can hold hidden opportunities, and a second set of eyes can save hundreds of thousands of dollars. When a project may stand to benefit from a Value Engineering Change Proposal, Benesch puts our value engineering experience to work. From accelerating project schedules to cutting costs and increasing value, our experts are proven leaders in developing VECP solutions.

Whether a project is at conception or construction is in full swing, our team tailors VE techniques to meet your needs, from major scheduling improvements to material alternates.

Benesch completed a VECP for the replacement of an ageing, nine-span two-lane roadway structure over the Duck River in Tennessee. The contractor engaged Benesch in the project to review the two-stage construction plan and identify a design that would reduce cost, enhance performance and increase constructability.

Our VECP identified an opportunity to complete the project in one construction phase within the existing right-of-way. The design offered increased safety during construction for the contractor and travelling public, and resulted in a total savings of $700,000 for the client.