Exploring Four Solutions to Complex Steel Erection Challenges

Every project, big or small, comes with its own set of challenges, whether it’s drainage issues, complex staging needs, endangered species in the area—the list goes on. But no matter the challenge, the project team must find a solution.

When it comes to complex steel erection challenges, Benesch’s Matt Hellenthal is often called on by contractors to leverage his expertise. In this article, Matt shares four recent projects that faced various challenges, explores the solution for each and provides key insights to remember for future projects.

Meet the Expert

Burlington Northern Santa Fe Railroad over the Central Tri-State Tollway

Hinsdale and Western Springs, Illinois

To accommodate the widening of I-294, the bridge carrying BNSF tracks over the tollway needed to be reconstructed. This had to be done in a way that would mitigate both rail and roadway disruptions. The solution was to erect the 78-ft., 6-in.- and 108-ft, 6-in.-long steel plate girder spans adjacent to the site on shoring towers before they were rolled into place using self-propelled modular transporters (SPMTs). The move would take place during a short outage window.

Benesch was brought on to create the erection plan and evaluate the superstructure for the SPMT move. To prepare for the move, we performed highly accurate weight takeoffs and center of gravity calculations for coordination with the SPMT vendor. From erection on the temporary shoring to lowering the girders on the substructure, we ensured the superstructure remained structurally adequate for stresses and stability, which included consideration of dynamic effects while in motion.

Key Insight: Know What Could Go Wrong

Of course, we always hope that a move will go seamlessly, but we also know to be prepared for challenges. In this case, all went well until an inspection revealed ¼” gaps between the sole and top plates of some bearings. We considered four possible causes for the gaps: steel fabrication error, improper elevations when the cross frame bolts were torqued, a seat elevation error or racking during transport.

The culprit? A seat elevation error. Once we figured that out, we developed a plan to fix the issue. With the proper geometry determined, we were able to jack and shim the bearings to ensure equal distribution of load to the bearings upon release.

Metra Milwaukee District West Line over the Fox River

Elgin, Illinois

In Elgin, Illinois, a bridge carrying the Metra Milwaukee District West Line (MDW) commuter rail over the Fox River needed replacement. With a river below and U.S. 20 passing at a skew overhead, the plate girder spans would need to be erected off site. Sound familiar?

Similarly to the BNSF project, the contractor erected four 137-ft-long steel plate girder spans on temporary shoring towers in the nearby commuter parking lot and rolled the spans into position using SPMTs. Benesch was responsible for the erection plan, temporary shoring, and evaluation of the superstructure for SPMT move.

Key Insight: Expect the Unexpected

As if the project wasn’t already challenging enough, something unexpected happened—a freight train derailment damaged and shifted the spans on top of the temporary shoring in the commuter lot. We had to work quickly with the contractor and the owner to assess the impacts and address any deficiencies in the temporary shoring. Repair plans for the permanent girders were also required due to various knicks, dents, and bends to the flanges and stiffeners.

30 Crossing

Little Rock, Arkansas

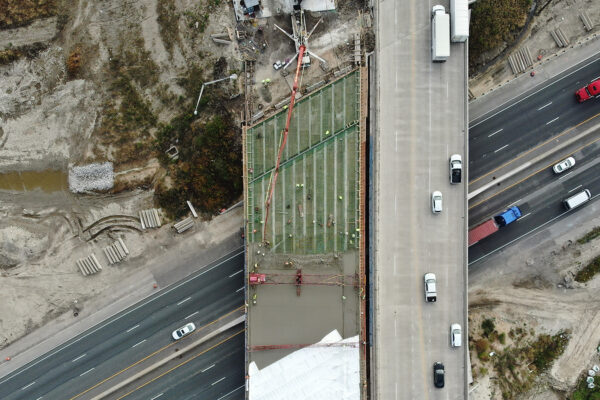

As part of a project to enhance one of the most traveled roads in Arkansas, the I-30 bridge over the Arkansas River in Little Rock was replaced using a design-build delivery method. The 1,366-ft long bridge carries traffic over the river using 126-in.-deep steel plate girders.

Benesch was contracted to create an erection plan that utilized various temporary works, including temporary bents and pier brackets.

Key Insight: Control Structural Behavior at Every Stage

To create a constructable and efficient erection sequence, we had to manage structural behavior at every stage. A critical component of this is looking at 3D structural behavior, even if a bridge is straight and non-skewed, to ensure deflections and rotations can be accommodated with each pick. Because partially erected spans still roll in various directions, we knew that the ability to connect cross frames and splices would be impacted, and we were able to plan the sequence, support locations and omission of cross frames accordingly.

Similarly, having upward deflection of cantilevered ends is always critical to ensuring that the next segment can be erected and the field splices can be connected.

Marseilles Dam Repairs

Marseilles, Illinois

After seven runaway barges collided with the Marseilles Dam due to a strong current from heavy rainfall, the U.S. Army Corp of Engineers got to work repairing two gates and replacing three others. With a utility bridge carrying power and fiber optic lines over the center of gravity of each gate, Benesch was tasked with coming up with an erection solution to get the 80-ton gates in place without relocating the utilities.

Key Insight: Be Prepared to Brainstorm, Design and Refine

To solve this challenge, we started by brainstorming with the contractor how a C-shaped rigging beam, much like that used for handling material spools, could be used. With a back-of-the-envelope design in hand, we moved on to design. We conducted traditional analyses supplemented by finite element modeling that was used to evaluate local stresses and buckling. One of our main goals was to try for ductile behavior, with yielding controlling over buckling.

Our initial design, consisting of wide flange beams, had inadequate buckling resistance (torsional mode) and needed refinement. After adding cover plates in our model to convert the vertical member into a tube, we found that yielding now controlled. From there, the C-shaped rigging beam was fabricated, load tested, inspected and successfully used to remove and replace the gates.

While each of these projects presented their own unique challenges, they all had something in common—a solution that required Matt and his team to embrace a problem-solving mentality, focus on structural behavior, communicate effectively and think outside of the box.

For more insights from Benesch experts, click here.