Artificial Intelligence, Machine Learning Enhance Pavement Assessment Workflow

A new workflow used for detecting cracks and other defects in pavement received global recognition from Bentley Systems this week. Developed by Benesch Technical Manager Bret Tremblay alongside several partners at Bentley Systems, the Artificial Intelligence (A.I.)/Machine Learning (M.L.) Driven Pavement Crack Detector workflow received Bentley’s Founders’ Honors as part their global 2023 Going Digital Awards in Infrastructure. This prestigious award, selected by Bentley’s founders, is only granted to a handful of outstanding projects among the hundreds of submissions received each year.

As existing pavement sections continue to deteriorate—on roadways, bridges and highways, at airports and in parking lots—demand for inspection and maintenance continues to grow. Traditional crack detection methods, which use what is known as a boots-on-the-ground approach, involve inspectors walking the pavement to take photos and measurements with a tape or wheel in order to classify and analyze deterioration. Knowing this method isn’t the most efficient, Benesch’s Bret Tremblay sought to leverage an existing partnership with Bentley Systems to explore how consultants could better utilize digital technologies to streamline the entire crack detection process.

The result of his efforts is an automated pavement crack detection workflow with the potential to revolutionize the way pavement assets are analyzed and managed. Powered by AI and ML, the new technology improves efficiency and accuracy of data collection activities while reducing inspectors’ exposure to environmental hazards and interruptions to area traffic.

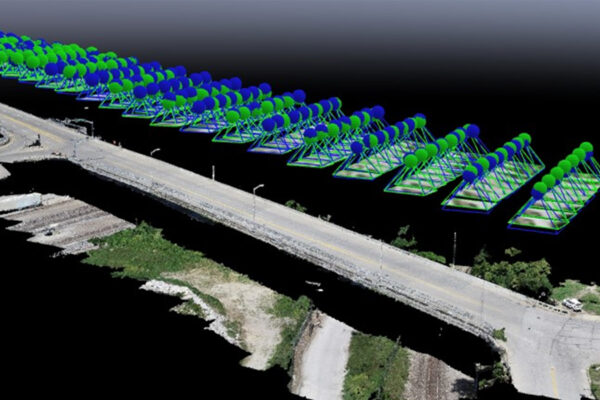

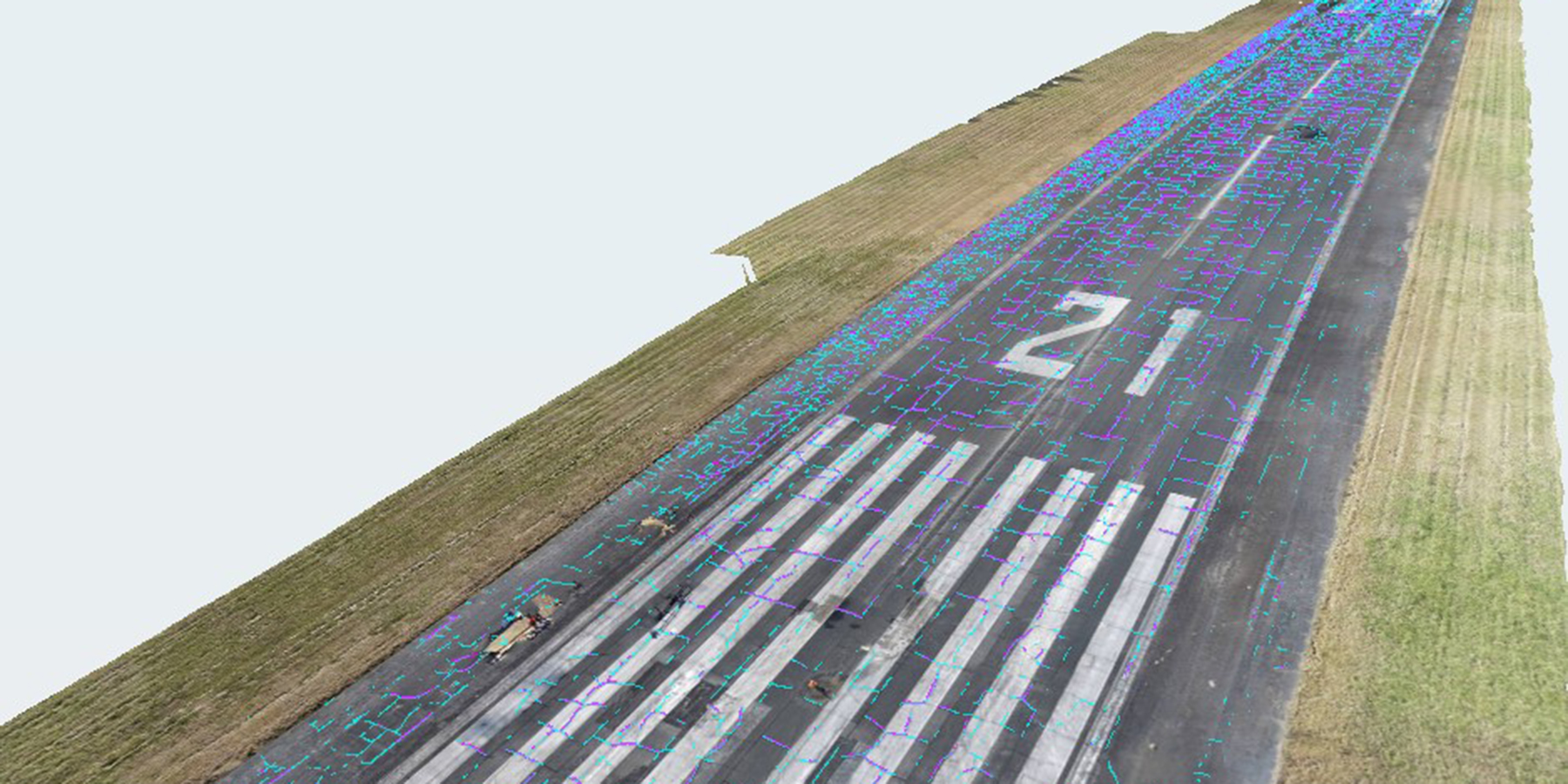

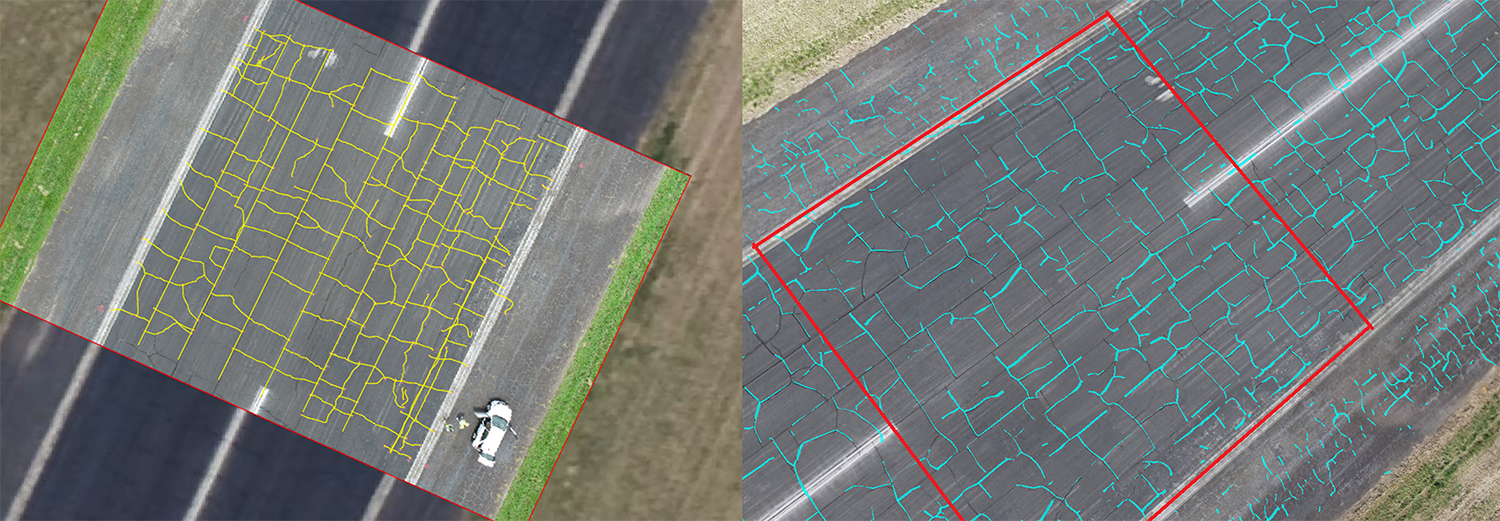

This new technology utilizes a Digital Twin model, which is created by flying a drone over the project site to collect high resolution aerial images that are stitched together to create a 3D model of the site. The user then feeds the model through the Pavement Crack Detector software to identify and analyze cracks. The software allows the user to tailor the detector to the specific needs of the project and, like other A.I. and M.L. technologies, it becomes smarter as more data is provided—not only in terms of detecting cracks but also, for example, distinguishing joint lines from cracks. The detector classifies every crack and adds attributes to give each one a distinct identity. Subsequently, this information can be exported by the user into project plan sheets or other platforms for further analysis.

The detector has been put to the test on multiple projects and thus far has yielded excellent results. Over the course of these projects, field time was reduced by an estimated 75%, along with a 75% reduction in vehicle traffic and airport runway closures. Furthermore, the results showed that using this technology will significantly reduce the amount of time it takes for CAD users to digitize linework.

“We are excited and confident in our ability to continue pushing this innovative technology forward in the service of our clients,” said Bret.

Even in its early testing phase, this product is the first of its kind to exist, both with Bentley and via other technologies. “This could be a game-changer for inspection data collection in the AEC industry,” Bret continued. “By utilizing the Pavement Crack Detector, more ground can be covered in less time, providing faster and more extensive survey data. All of this translates into a positive impact on our communities, both locally and globally.”

Learn more about the Founders’ Honors recipients here.

Based in Chicago with offices across the U.S., Benesch is a proud participant in Bentley Systems’ Early Adopter Program. We are dedicated to harnessing the power of 3D visualization, Artificial Intelligence and augmented reality tools in ways that will further the AEC industry and benefit the critical assets owned and maintained by our clients.