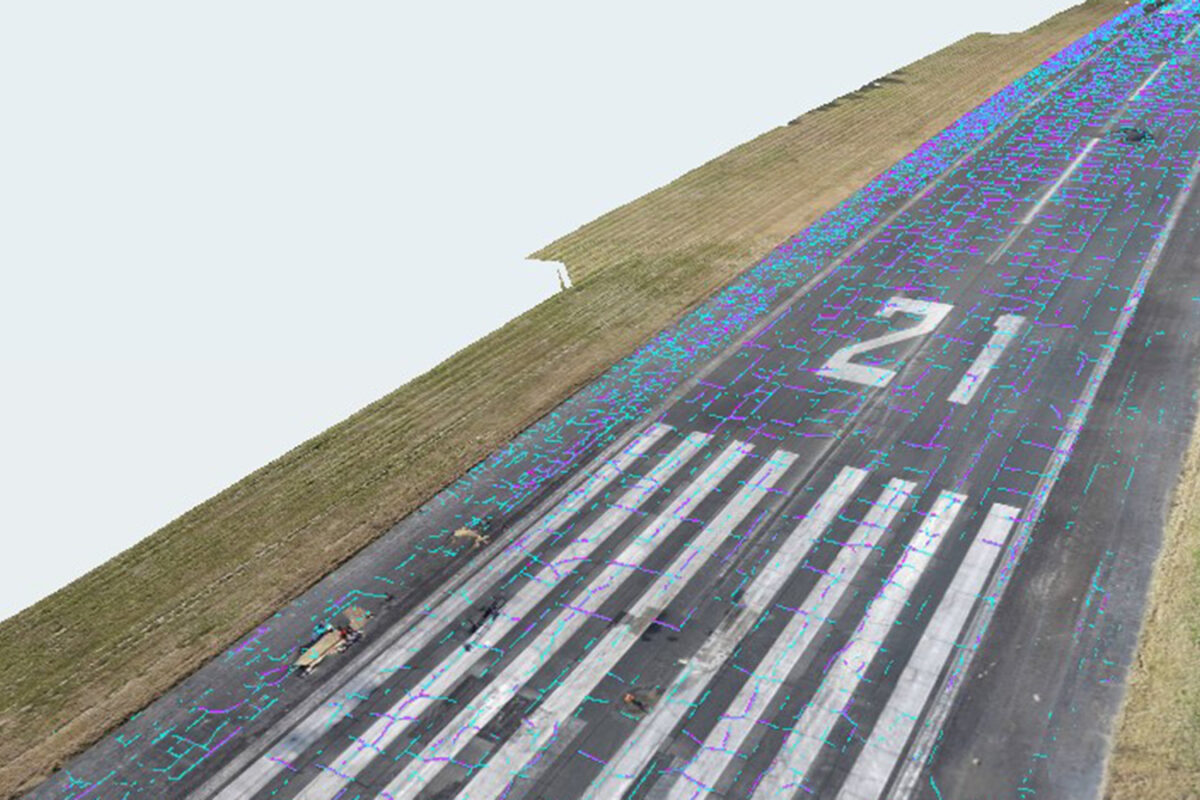

Kearney Regional Airport Runway 18/36

Benesch completed a preliminary design phase in which seven different pavement section alternatives were evaluated for the reconstruction of Runway 18/36. The new pavement structure options were evaluated not only on initial cost but also on 20-year life cycle costs accounting for routine maintenance. An additional component was the need to correct the runway profile to meet FAA standards for C-II category aircraft. After analyzing three profile alternatives, two distinct pavement sections were selected: a full-depth reconstruction (concrete surface) for the northerly 1,900-feet and concrete “whitetop” over an asphalt debonding layer for the remainder of the runway.

Another component of the design was realigning the north and south end connecting taxiways to be perpendicular to the runway. The original taxiways were connected to the runway at 45-degree angles, making it difficult for pilots to clearly see up and down the runway for approaching or departing aircraft.

After the project was successfully bid, and a few months before construction was set to begin, the airport lost their commercial air service provider. NDOT quickly re-solicited to find a new commercial air service. The decision was made to begin construction as soon as possible, pushing the completion date three months sooner than originally planned. After a new air service provider was selected, pavement sections had to be redesigned to accommodate the heavier aircraft that would now be operating at the airport.

Pavement milling, removals and perforated-pipe subdrain (edge drains) installation began in the fall and continued through the winter. Construction of new pavement began in March, and quickly accelerated toward completion by the end of August, including almost $7 million worth of work completed in the last three months. In order to meet the shortened schedule and ensure quality construction, frequent and targeted coordination between all parties was essential, especially related to material testing. Simultaneous operations for concrete paving, asphalt paving, subgrade density testing, documentation and quality controls were required from the material testing technicians and laboratory in Benesch’s Lincoln office.

In all, Benesch’s accredited geotechnical laboratory was responsible for the following QA (per FAA specifications) material testing:

- P-152 Subgrade/Soil

- P-208 Aggregate Base Course

- P-219 Recycled Concrete Agg. Base

- P-401 Surface Course Asphalt

- P-403 Base and Leveling Course Asphalt

- P-501 Portland Cement Concrete (PCC) Pavement

- P-610 Structural Concrete

Furthermore, the reconstruction of the runway involved relocating and replacing four separate FAA-owned NAVAID facilities. Quick decisions about timing and the project schedule had to be coordinated between the Owner, Contractor, FAA, NDOT and Benesch, but also with FAA’s NAVAIDs Engineering Services group.

Practice Areas

Services

Awards

- 2019, Engineering Excellence Merit Award, American Council of Engineering Companies - Nebraska

- 2018, Best Portland Cement Concrete Overlays Project, Nebraska Concrete Paving Association

- 2018, Best Small Airports Project, Nebraska Concrete Paving Association